Troubleshooting The Dual Boiler BES920 Steam Boiler

Share

In this post, we will cover some steps you can take if your machine is no longer heating up - most often following a descale.

If you own a Breville BES920, and specifically one that has the older version 1 or 2 steam boiler, descaling the machine comes with significant risks. This article will outline the dangers involved, explain the underlying issues, and provide guidance on how to mitigate the risks.

Why the BES920’s Sensors Are Problematic

The Breville BES920, like the other dual boiler models, relies on water level sensors to determine when to activate the pump or heat. However, versions of the BES920 manufactured before late 2022 (I believe it's week 42, so 2242) with other older water level sensors are highly susceptible to failure, particularly during the descaling process. Here’s why this is a concern:

- Descale Solution Contamination: During the descaling process, the descale solution can inadvertently come into contact with the probes. This contamination mimics the presence of water, leading the machine to misinterpret the water levels in the boiler.

The Consequences of Probe Contamination

When descale solution residue affects the probes, one of two scenarios can occur:

- Red Probe Contamination (Pump Control): The red probe governs the water pump. If it becomes contaminated, the machine will falsely register the boiler as full. The result? The boiler won’t heat up. While this issue is inconvenient, it’s fixable—though you may need to remove the top cover to clean the probe thoroughly.

- Blue Probe Contamination (Heat Control): The blue probe is responsible for controlling the heating element, and contamination here can lead to catastrophic consequences. If the machine believes the boiler is full due to false readings, it will activate the heating element before the boiler is actually filled. This causes rapid overheating, which can:

-

- Blow the thermal fuse.

- Permanently damage the heating element.

- Require a complete boiler replacement, costing upwards of $600.

How to Protect Your Machine

To reduce the risks associated with descaling your BES920, consider these precautions:

- Use a Professional Descaling Service: If you’re uncertain about handling the process yourself, consult a professional technician who can descale the machine safely.

- Avoid Overdosing: Ensure that you only use the recommended (or less) amount of descale solution to minimize the risk.

- Replace the Probes: If possible, consider replacing the probes with new ones. Brand new probes still have their protective coating and are not vulnerable to this.

- Follow the instruction outlined in this video to help you assess the condition of your machine before carrying a descale: Will Your Breville Survive a Descale? - Part1

Do I have the older, version machine?

Breville changed to the new version of steam boiler around the middle of 2022, but this is not a guarantee as some machines appear to have later dates on them - maybe relating to certain colours or countries.

Here is how to find out which version you have:

- Remove the top lid. The older version has water level probes held in with clips. The newer ones have a compression fitting nut on them. The red probe is also in the middle and on the right for the older ones.

Conclusion

Owners of pre-2023 models especially, need to exercise caution when descaling as contamination can lead to costly repairs.

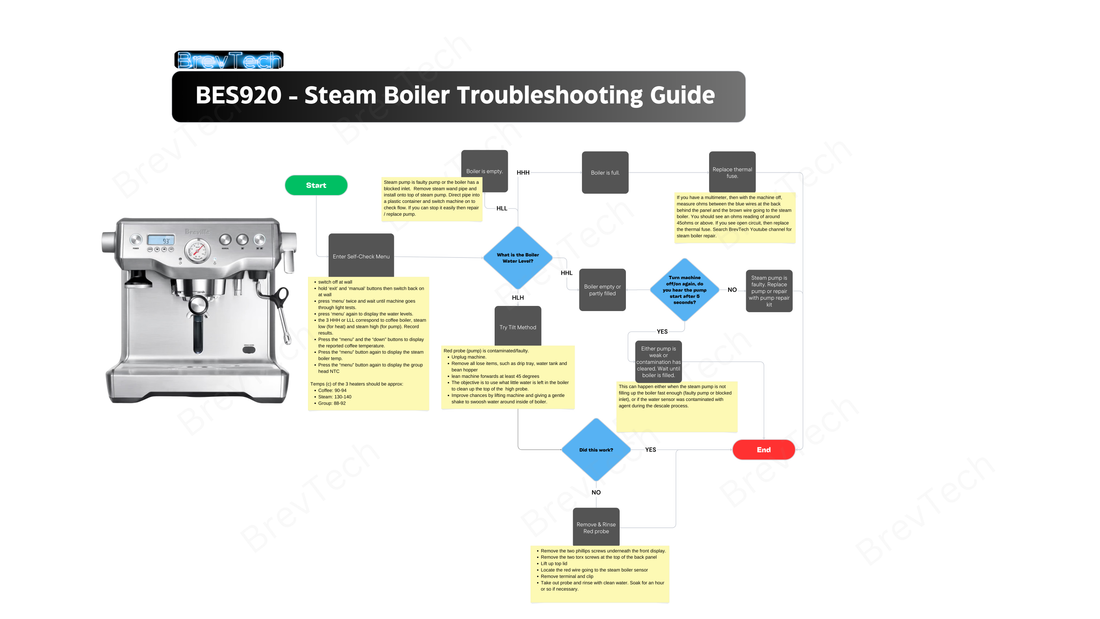

To further assist you, I’ve created a flowchart that allows you to troubleshoot common issues related to descaling and water level sensors (click to open in new tab):

5 comments

Hi,

I have a BES980 with the steam probes with clips. The thermal fuse blew upon descaling (steam boiler would not heat up at all), so I changed the thermal switch and fuse on the steam boiler. I also replaced all orings, steam probes, cleaned all 3 solenoids while the machine was open. After doing this, I powered the machine on and the steam pump heated up, only it continued to heat beyond the set level (I only let it go slightly higher than set temp before unplugging the machine). I took this to mean that there was an issue with the triac and octocoupler so I proceeded to attempt to replace all 3 trials and octocouplers (I purchased a full set so thought why not 🤦♀️), however due to my level of experience doing this, I may have damaged the triac board in the process. Upon turning the machine on after doing the triac board repair, neither the coffee boiler nor the steam boiler heat up now, however one of the pumps turns on. Can I take this to mean I have damaged the triac board and I should just replace the whole triac board to get my machine back up and running? Could a damaged triac board result in no resistance when testing the blue and brown cables at the back (as well as the blue with red)?

Hey guys what’s the first thing to check if there’s no power or back light to machine once plugged in and pressing power buttons does nothing . Is there a main fuse ? If so what’s the location

I’ve

Tried drying it for two weeks to try to see if it’s anything that has do with sensors , but no luck power it on .

Hi! I have the HHL issue and am replacing the probes since the appeared damaged. I am also in the process of replacing the steam valve which was really corroded (waiting on the part to install). In the meantime I was trying to find a resource on repairing the steam pump incase it was more than a red probe issue. I purchased the dual boiler survival kit and see there is a small black o-ring for the boiler pump. Is it a simple remove and replace o-ring or are there other parts in the pump that I need to look at to see if I need to replace instead of just refurbish? I switched out the o-ring and ball in the brew pump. Thanks so much for your resources. they have been really helpful. – Lori

Yes they do

Hi there, do newer 980s and 990s also have the new boiler and therefore less problems with descaling?

Because in an online shop I found two different versions of steam probes for 980s.