Repairing a Dripping Hot Water Spout on the Breville Dual Boiler (BES920)

Repair a Dripping Hot Water Spout — Breville Dual Boiler (BES920)

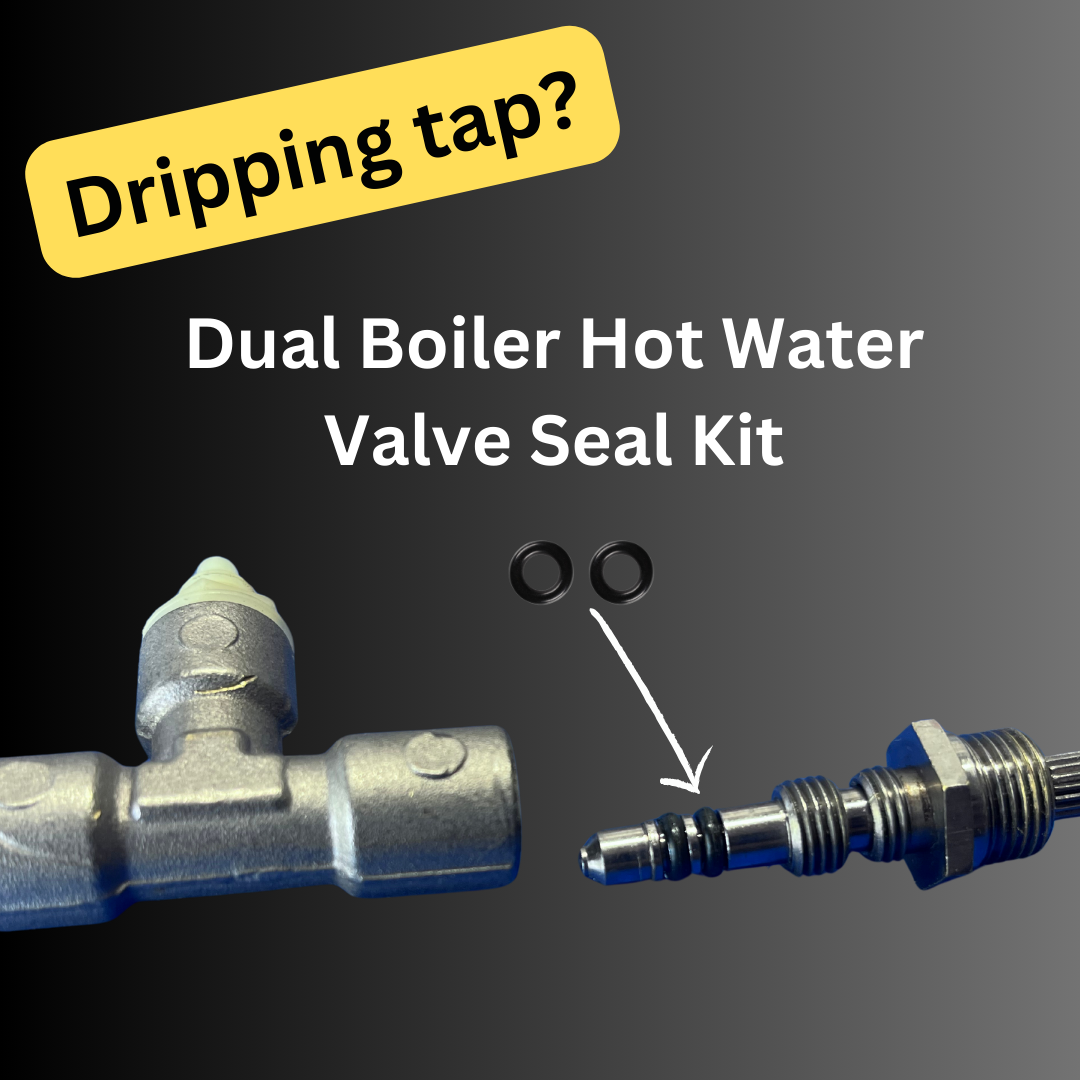

If your hot water spout drips even when closed, the culprit is usually the two O-rings inside the needle valve — not the solenoid or boiler. This guide shows how to access the valve, replace the O-rings, and restore a proper seal.

Fixes

- Dripping hot water spout

- Hot water leaking when valve “closed”

- Worn/flattened O-rings in needle valve

Tools

- Phillips screwdriver

- T20 Torx driver

- Small pliers

- 14 mm spanner

- Adjustable spanner

Time

~45 minutes

Step-by-Step: Needle Valve O-Ring Replacement

Power Down & Cool

Unplug the machine and let it cool fully.

Remove Outer Screws

Remove the two Phillips screws underneath the front panel and the two Torx screws at the back.

Lift the Lid

Carefully lift the lid to expose the control panel and valve area.

Remove the Knob & Inner Screw

Grip the hot-water knob and pull straight off (rubber glove helps for grip). Then remove the Philips screw inside the shaft.

Remove Microswitch & Knob Core

Undo the two screws holding the microswitch; use a flat-blade screwdriver to release the remaining part of the knob.

Expose & Free the Valve

Access the two screws holding the valve bracket, then remove the two hose clips with pliers.

Remove the Valve Assembly

Take out the final two screws to release the valve and withdraw it for bench work.

Open the Valve Body

Use large pliers or a socket to remove the retaining nut, then note the order of parts as you disassemble.

Access the Needle & O-Rings

Secure the valve body with an adjustable spanner and unscrew the internal needle to expose the two O-rings.

Replace O-Rings & Reassemble

Cut off the worn O-rings, install new ones from the kit, apply a little food-grade grease, and reassemble the valve in the same order. Reinstall in the machine and test for leaks.

Tags: Breville BES920 hot water leak, dripping spout, needle valve O-rings, hot water valve repair, Dual Boiler maintenance